limitation on the thickness of specimens for a hardness test|hardness testing scale : Big box store Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary to have properly prepared the surface of the sample to . Le autoclavi, conformi alle linee guida del Decreto Legislativo numero 81 del 2008 sul Testo Unico della Sicurezza sul Lavoro, sono apparecchiature che sottopongono gli strumenti e i materiali utilizzati durante .

{plog:ftitle_list}

Safety Basket Electric Supply Optional Basket Perforated Basket Plain Basket Custom-made .

During specimen testing or coupon block verification, the spacing between indents, as well as from the material edge, must be properly maintained to prevent any adjacent indents or worked edge from influencing the next test. Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary to have properly prepared the surface of the .During specimen testing or coupon block verification, the spacing between indents, as well as from the material edge, must be properly maintained to prevent any adjacent indents or worked edge from influencing the next test. Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary to have properly prepared the surface of the sample to .

It is important to note that Brinell hardness testing may not be suitable for materials with very high hardness or thin and small components where a smaller indentation size is desired. In such cases, alternative hardness testing methods like Knoop or Vickers may be more appropriate.The specimen must be thick enough for the indent not to cause any visible deformation on the underside of the specimen (supporting surface). This means that, according to the standard, the specimen must be at least eight times thicker than the indentation depth of the Brinell ball.What is the limitation on the thickness of specimens for a hardness test? Explain. Calculate the minimum thickness for one specimen for the Rockwell test and one forIn order to prevent the test base (e.g. the test anvil) from affecting the test result in any way, a minimum specimen thickness must be observed with the Brinell method (acc. to ISO 6506). This minimum specimen thickness must be eight times the .

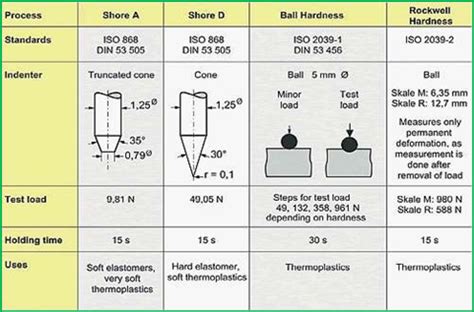

A sample should have a minimal thickness that is at least ten times the indentation depth is expected to be attained. There are minimum thickness recommendations for regular and superficial Rockwell methods. Scales. Sometimes it is .Limitation in applying the method on thin specimens of very hard materials (see Brinell method, minimum specimen thickness). The process is slow (by comparison with the Rockwell method). The test cycle takes somewhere between 30 and 60 seconds, not including the time taken to prepare the specimen. for testing hardness in plastics, like Shore (Durometer), Rockwell, the Ball indentation hardness test and Barcol. This Application Note will focus on hard-ness testing of metals, the mechanical preparation of the specimens and the different parameters influencing the in-dentation hardness testing result.The specimen thickness (the specimen thickness must be at least 1.5 times the indentation diagonals, i.e. the minimum specimen thickness must be between 0.085 and 6.5 mm)

During specimen testing or coupon block verification, the spacing between indents, as well as from the material edge, must be properly maintained to prevent any adjacent indents or worked edge from influencing the next test. Hardness testing does have some limitations and challenges that can affect the accuracy and repeatability of hardness results, some of which are listed below: It is necessary to have properly prepared the surface of the sample to .

It is important to note that Brinell hardness testing may not be suitable for materials with very high hardness or thin and small components where a smaller indentation size is desired. In such cases, alternative hardness testing methods like Knoop or Vickers may be more appropriate.The specimen must be thick enough for the indent not to cause any visible deformation on the underside of the specimen (supporting surface). This means that, according to the standard, the specimen must be at least eight times thicker than the indentation depth of the Brinell ball.What is the limitation on the thickness of specimens for a hardness test? Explain. Calculate the minimum thickness for one specimen for the Rockwell test and one forIn order to prevent the test base (e.g. the test anvil) from affecting the test result in any way, a minimum specimen thickness must be observed with the Brinell method (acc. to ISO 6506). This minimum specimen thickness must be eight times the .

A sample should have a minimal thickness that is at least ten times the indentation depth is expected to be attained. There are minimum thickness recommendations for regular and superficial Rockwell methods. Scales. Sometimes it is .Limitation in applying the method on thin specimens of very hard materials (see Brinell method, minimum specimen thickness). The process is slow (by comparison with the Rockwell method). The test cycle takes somewhere between 30 and 60 seconds, not including the time taken to prepare the specimen. for testing hardness in plastics, like Shore (Durometer), Rockwell, the Ball indentation hardness test and Barcol. This Application Note will focus on hard-ness testing of metals, the mechanical preparation of the specimens and the different parameters influencing the in-dentation hardness testing result.

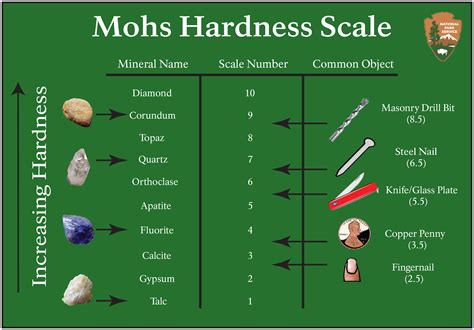

how to read a gemstone refractometer graph

standards for hardness testing

hardness testing scale

hardness testing process

¿ como funciona una autoclave? El funcionamiento de una autoclave inicia permitiendo la entrada o generación de vapor de agua pero al mismo tiempo haciendo una restricción del mismo a la salida con el fin de que la presión se .

limitation on the thickness of specimens for a hardness test|hardness testing scale